support hotline:+86-186-8219-5565 | Company email:sales@m-qo.com

support hotline:+86-186-8219-5565 | Company email:sales@m-qo.com

This blister weldng and cutting machine is multipurpose machine, for it can be used for industry like PU leather cover for pad, automotive parts and car interior elements, safety vests, reflective signs, inflatable toys, cosmetics,folding packing box,.etc. It also is especially designed for high frequency welding is a perfect machine for production of blister packages

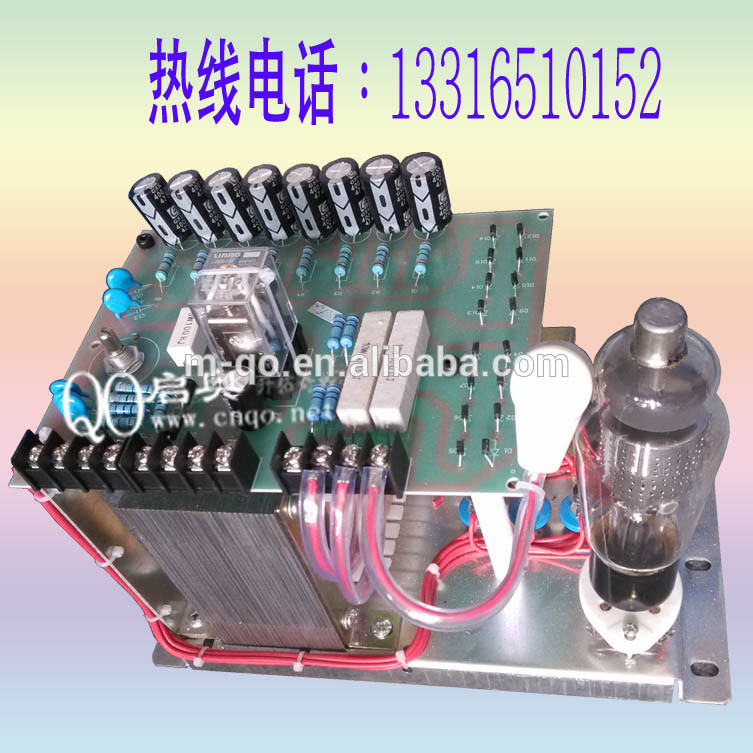

The high frequency blister packaging welder,bilster weldin and cutting machine, by Shenzhen QIAO equipment CO., LTD, is made for various industrial HF welding and sealing applications. It is designed for applications requiring precision large flat surface for product positioning and complex shape welds.

The high frequency blister welding and cutting machine series have high frequency power outputs from 5KW to 15KW.

Machine is with special quick change electrode holder. Custom designed tooling and welding upper platen are available on request.

Application:

1. To seal blister of PVC, PET-G, PET-GAG, A-PET...

2. Clear blister packaging

3. Plastic clam-shell packaging

4. Plastic Blister with plastic blister packages

5. Plastic blister with cardboard packages

6. Positive/negative blister forming and packaging

It is especially designed for HF welding is a perfect machine for production of blister packages, But it is multipurpose machine.

Mainly used in PVC, APET, PETG, GAG environmental protection material double-sided blister packaging, blister sealing kit packaging, toothbrush seal packing, EVA cloth leather, leather, OPP, PU material welding and cutting.

It can be used for industry like PU leather cover for pad,, safety vests, reflective signs, inflatable toys, cosmetics, folding packing box, automotive, medical, rehabilitation, packaging, recreation, textile and clothing, reflective garments,.etc.

specification:

Packing & Delivery

| Welcome to choose and the welding and cutting machine, synchronous fusing machine, high frequency synchronization fusing machine, can also according to customer request custom all kinds of equipment |